Working within existing facilities, whether modernizing a building or expanding a busy airport terminal, demands absolute certainty about what’s already there. Every beam, column and connection matters. With decades of experience delivering projects in complex, operational environments, Hensel Phelps brings clarity to these challenges through our in-house Reality Capture processes, helping teams identify and mitigate risk before construction begins.

Laser scanning is a core capability within that effort, capturing millions of data points per second to create a highly detailed, three-dimensional view of existing conditions. Supported by complementary tools such as ground-penetrating radar, x-ray imaging, geospatial mapping and visual surveys, this approach allows teams to move forward with confidence, knowing decisions are grounded in accurate, real-world data.

When Hensel Phelps began work on the Nashville International Airport (BNA) Terminal Lobby and International Arrivals Facility, the design was still in its earliest stages. To give the project a strong start, the team conducted more than 1,200 laser scans of the existing terminal, creating a highly accurate virtual model of the building. The scans revealed what was possible, giving the Metropolitan Nashville Airport Authority (MNAA) and the project team the confidence to pursue bold design solutions, such as reducing 88 support columns to 32, bringing MNAA’s vision for a brighter, more open terminal to life.

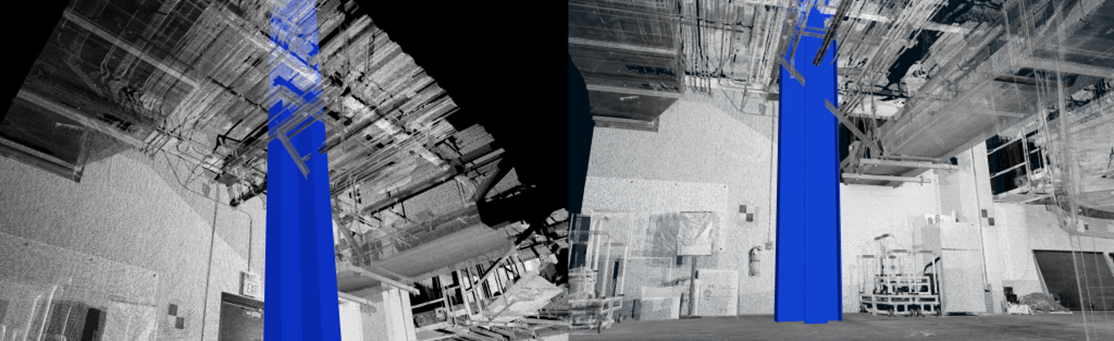

On the Eagle County Regional Airport Expansion and Remodel Project, Hensel Phelps demonstrated how laser scanning can bridge the gap between design intent and field execution. Before construction began, our team conducted comprehensive scans of the existing airport to document the exact locations and dimensions of all existing systems. This data became the foundation for a fully coordinated model, one that evolved alongside the design and guided decisions throughout construction.

The coordinated model allowed the team to perform continuous clash detection and maintain alignment between disciplines as the design developed. One of the model’s most critical benefits came from the ability to identify and precisely locate structural steel penetrations during the design and fabrication process. By knowing exactly where every penetration needed to occur, the team achieved significant efficiencies in system installation and field execution.

The technology also proved invaluable during the renovation of the TSA security checkpoint and adjacent office spaces. Using the coordinated model, Hensel Phelps could visualize and communicate complex design decisions to project stakeholders, particularly in the tight ceiling and roof spaces where systems competed for limited clearance. This proactive approach enabled the team to streamline coordination efforts and deliver the renovated TSA checkpoint quickly, minimizing impacts to airport operations.

Hensel Phelps’ ability to perform laser scanning in-house gives teams and clients greater confidence in accuracy, frequency, and quick turnaround times.

Hensel Phelps continues to redefine what’s possible with reality capture technology. By meticulously documenting existing conditions, we enable project teams to virtually explore, coordinate and solve challenges before a single beam is set in place.