Learn how Hensel Phelps delivers complex construction solutions across markets by visiting our Projects Page.

About the Project

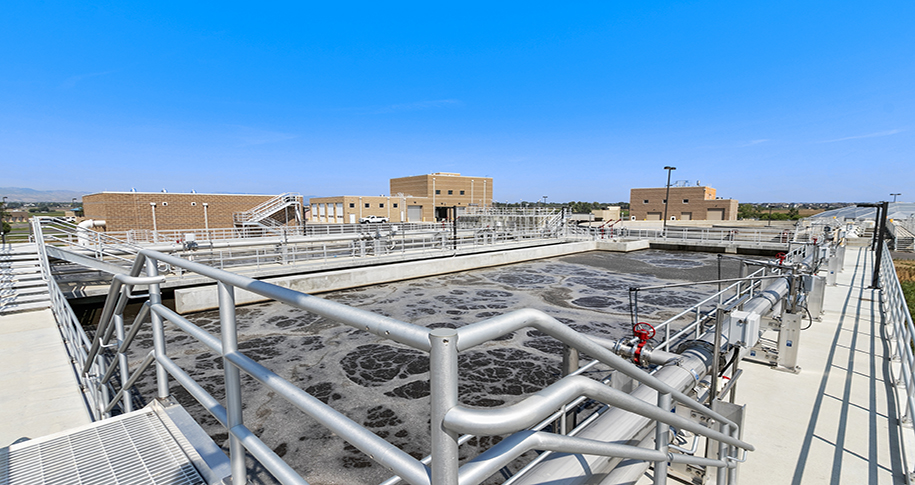

Hensel Phelps served as the Construction Manager at Risk (CMAR) for the Town of Wellington’s Project. The plant’s capacity was increased to 4.2 million gallons per day (MGD), with accommodations for a future build-out capacity of 6.9 MGD. The new 15,352 SF treatment building was constructed over the two treatment trains and included an electrical room, pipe gallery, equipment room and observation decks over the basins. The 3,023 SF chemical building was built over eight chemical storage tanks in the concrete chemical containment structure, which included chemical feed equipment, an electrical room and a mechanical room. The 1,998 SF ozone building was constructed over a two-level concrete foundation to house the ozone generation and injection equipment and electrical room.

The project included a pipeline ozone contactor, three solids drying beds, two equalization ponds, a recycle pump station, a backwash equalization pump station, modifications to the existing clearwell, connection to emergency supply from ditch, site and yard piping modifications and modifications to the existing chemical building. Additional work included site improvements, electrical, instrumentation and control and system start-up. The preconstruction phase included delivering a progressive GMP and the procurement of the ozonation system equipment. Additionally, ENR Mountain States & Southwest announced the Wellington Water Treatment Plant Expansion as the 2025 Water/Environment Best Project.

Hensel Phelps and its team on this project have proven to be Wellington’s valuable partner for years and have consistently maintained an outstanding relationship with the Town. Excellent quality of work performed by Hensel Phelps and their trade partners.”

DAVE K. MYER, P.E., ENGINEER III

TOWN OF WELLINGTON

Challenge

Influent Pumping Capacities

During the summer of 2022, the Town of Wellington lost all influent pumping capacities to its water treatment plant and was going to run out of water within a day. This would have resulted in a disruption of service to the town’s residents.

Solution

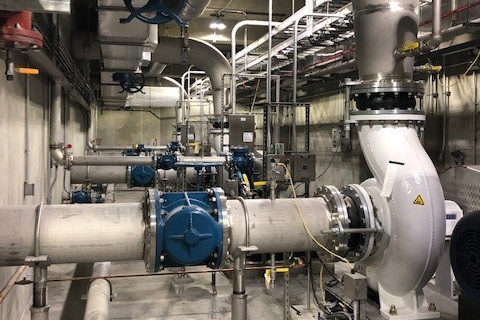

Variable Frequency Drive (VFD)

The Hensel Phelps Water team and their electricians stepped in, used a Variable Frequency Drive (VFD) out of an existing well across town, and got the water treatment plant up and running with water flowing to the plant before the town ran out. The team was also able to procure temporary diesel-powered pumping units as a backup if the VFD change-out didn’t work.

Results

Prompt and Effective Response

The VFD change-out was successful, and the likelihood of water becoming unavailable to the community was averted. The Town of Wellington was extremely thankful for the team’s prompt and effective response. This incident occurred at the beginning of the Wellington Water Treatment Plant Expansion project and jump-started the team’s relationship with their client. The Water team went above and beyond to help their client in a time of need and created a lasting relationship.

Related Projects

-

Water + Wastewater project

Repair Wastewater Treatment Plant Effluent Pump Station Building 1357 Learn More -

-

Water + Wastewater project

South Fort Collins Sanitation District Water Reclamation Facility Expansion Learn More -

-

-