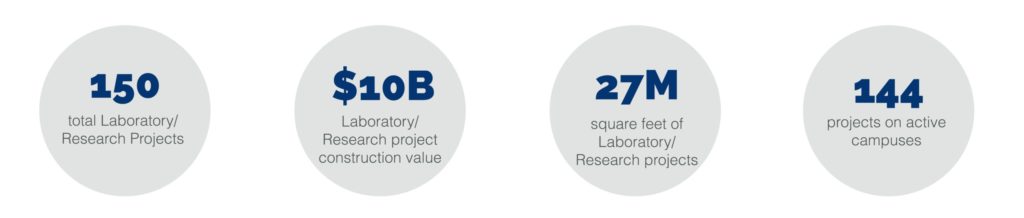

Across the globe, scientists are performing research critical to the advancement of medicine, environmental monitoring and industrial processing. As these sciences become more advanced, research and laboratory spaces must follow suit. Hensel Phelps has supported over $4 billion worth of these spaces by focusing on predictability of service from preconstruction through project turnover.

During preconstruction, Hensel Phelps project teams host end user meetings to gain an understanding of the science and research that will take place in the future lab spaces. The information gained during these sessions allows Hensel Phelps to work with trade partners in budgeting what works for the project and the scientists, becoming a bridge between the scientists and the design team.

The effort put forth during these early phases must also support a successful commissioning process, as it is critical that a research laboratory functions the way it is intended. In addition to fire alarm testing, egress and elevator drop tests, laboratories include fume hoods, eye wash stations, cleanrooms and glove boxes that require third-party commissioning consultants. Hensel Phelps ensures enough time is built into the project schedule to perform this testing while still meeting move-in dates and final completion.

Predictability in Practice: National Institutes of Standards and Technology (NIST) Building 245 Modernization

The National Institute of Standards and Technology (NIST) selected the Hensel Phelps | ZGF Design-Build team for a Single Award Task Order Construction (SATOC) contract to modernize and expand Building 245, a radiation physics laboratory on the historic Gaithersburg, Maryland campus.

During design, the Hensel Phelps team conducted multiple meetings to guarantee that laboratory adjacencies were planned to consider both cost and function. They also worked to evaluate how individual decisions would affect other areas of the project. To ensure researchers’ needs were met, Hensel Phelps engaged six research divisions including 12 individual researchers, to review room data sheets. Through this exercise, Hensel Phelps realized that the client needed more than what was shown in the sheets. From there, they were able to trend specific items the client wanted to confirm that the project remained in budget and would fit their needs. The team also facilitated 3D walk throughs of the designed lab spaces, allowing researchers to interact with their laboratories. Staff feedback from these interactions had significant impact on the design process and allowed researchers to visualize their space and adjust as needed.

In addition to ensuring the new space supported the science it was intended to perform, Hensel Phelps focused on preventing disruptions to the ongoing research surrounding the project site. The 75,000 SF addition to Building 245 utilized a mat foundation to reduce the possibility for differential settlement. The structural configuration of the addition consisted of a robust concrete frame structure offering enhanced floor loading and vibration mitigation. In addition to engineering a solution that would minimize disruptions to the campus, Hensel Phelps collaborated with the owner to communicate campus outages through Disruption Access Requests (DAR). Utilized to assist in the overall coordination of any rooms that Hensel Phelps would be taking possession of for construction purposes or for rooms where there would be major construction impact, the form helped the team determine what workplans were necessary and provided the initial key communication with NIST entities. This process guaranteed continual operation of adjacent research through many touchpoints with the various research groups.

Throughout construction, the team held regular commissioning meetings with the owner and third-party radiological consultants to coordinate work prior to its start. This upfront planning minimized surprises and ensured that Hensel Phelps maintained a fully functional and safe facility that allowed the laboratory to reach its performance potential. The team also maintained a commissioning issues log and a punchlist log which were communicated to the owner weekly along with status updates. This fostered a clear and constant line of communication among the team.

At project turnover, Hensel Phelps will continue to provide predictability through transition services provided by Hensel Phelps Services. Operation and maintenance services will be provided to the newly constructed and renovated laboratory and office spaces, as well as for the unrenovated spaces before their renovation in future task orders. These efforts will assist in the coordination of service continuity and predictability as the phases of the project evolve.

As research and laboratory spaces continue to advance, Hensel Phelps remains an integrated partner, ensuring that our project teams build close bonds with our owners and end-user groups to clearly understand their central needs and to support their missions.